- Home

- About us

- Mineral Processing EPC

- Products

-

- Crushing

- Screening

- Grinding

- Classifying

- Agitation Equipment

- Flotation

- Gravity Separation Equipment

- Magnetic Equipment

- Thickening

- Dewatering Machine

- Gold Extraction Equipment

- Feeding

- Transmission Equipment

- Iron Removal Equipment

- Automatic Control Equipment

- Wear – Resistant Rubber Products

- Valves

- Hydrocyclone

- Pumps

-

- Solutions

-

- Gold CIP Production Line

- Gold CIL Processing Line

- Gold Flotation Production Line

- Cu-Pb-Zn Dressing Process

- Gold Heap Leaching Process

- Molybdenum Dressing Production Line

- Quartz Sand Dressing Production Line

- Hematite Separation Process

- Phosphorite Flotation Equipment Production Line

- Manganese Ore Magnetic Separation Production Line

- Magnetite Separation Production Line

- Scheelite Flotation Production Line

- Fluorite Flotation Process

- Silver Flotation Process

- Barite Mineral Processing

- Antimony Mineral Processing

- Wolframite Mineral Processing

- Chrome Ore Mining Process

- Iron Ore Mining Process

- Tin Ore Mining Process

- Nickel Ore Mining Process

- Graphite Ore Beneficiation Process

- Tailings Re-Processing Line

- Titanium Mining Process

- Dolomite Mining Process

- Kaolin Mining Process

- Pyrite Mineral Process

- Zircon Ore Mining Process

- Magnesite Flotation Process

- More >>>

-

- Cases

- News

- Contact Us

Home > Products > Dewatering Machine>Drum Filter

Drum Filter

- Product Introduction

- A traditional external filtration type vacuum filter

- Filtering Area

- 3~50m2

- Product Improvement

- Revolution of cylinder is stepless adjustment

Advantages

Cylindrical external filtration type filter is normal filter realizing stepless speed change by adjusting the motor revolution.It has the advantages of simple structure, low price, convenient operation, little wearing parts etc..

Product Structure

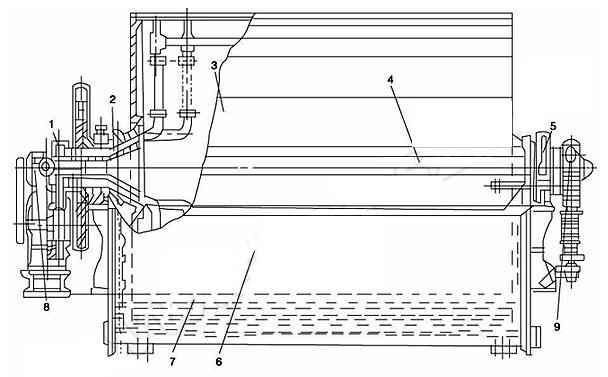

External filtration type drum vacuum filter consists of cylinder, transmission structure, allocation head, main shaft, agitation device, slurry tank, scraper and coiling device etc.

1. Left and right allocation head 2.Piping;3.Cylinder;4.Scraper;5. Main bearings;6.Slurry tank;7. Agitation device;8Transmission structure

Work Principle

The cylinder is main part of filter. The large size cylinder is made of welded steel plate, the small size made of cast cylinder, and some old-fashioned filter cylinder made of thick wood. The filter cylinder is divided to some filtering chambers by strip along the circumferential direction. These chambers are strictly sealed without ventilation between each other. Filter plate is laid on filter chamber forming a channel for filtrate and supporting filter cloth.

The cylinder is wrapped in filter cloth in order to ensure the sealing between each chamber.

There is a pipe at one end of the cylinder body which has the same number of channels with chambers.Each channel connects with corresponding filter chamber. The transmission mechanism drives the cylinder, and could transform several speeds.

Product Application

Mainly used for filtering fine particles, the products with low moisture containing nonferrous metal and non metal concentrate and flotation coal concentrate dewatering, etc., it can also be used for solid - liquid separation in mineral processing, metallurgy, chemical industry, papermaking and other departments.

Technical Parameters

| Model | Filter Area | Cylinder Spec. (mm) | Cylinder Rotating Speed (r/min) | Magnetic Induction (mt) | Filter Cake Moisture (%) | SuckingRate (m3/min.m2) | Gauge Pressure (kg/cm2) | Capacity (t/h) | Motor Model | Motor Power (kW) | Weight (kg) |

| GYW-3 | 3 | φ1600X700 | 0.5-2 | 80 | 8-11 | 1 | 0.1-0.3 | 6.0-9 | Y100L-6 | 1.5 | 3270 |

| GYW-5 | 5 | φ2000X900 | 0.5-2 | 80 | 8-11 | 1 | 0.1-0.3 | 14-18 | Y100L-6 | 1.5 | 3935 |

| GYW-8 | 8 | φ2000X1400 | 0.5-2 | 82 | 5-15 | 1 | 0.1-0.3 | 22-45 | Y100L-6 | 1.5 | 4755 |

| GYW-12 | 12 | φ2000X2000 | 0.5-2 | 87 | 5-15 | 1 | 0.1-0.3 | 33-65 | Y112M-6 | 2.2 | 5420 |

| GYW-20 | 20 | φ2550X2650 | 0.5-2 | 87 | 5-15 | 1 | 0.1-0.3 | 50-108 | Y132M2-6 | 5.5 | 6550 |

Guestbook

Please leave your message here! We will send detail technical info and quotation to you!

Related Products

Mineral Processing

EPC and Equipment

Tel: 0086 13025991453

E-mail: marketing@ytxinhai.com

Home

About us

EPC

Products

Solutions

Cases

News

Contact Us

3D Exhibition Room

sitemap

© 2014 Shandong Xinhai Mining Technology & Equipment Inc.