- Home

- About us

- Mineral Processing EPC

- Products

-

- Crushing

- Screening

- Grinding

- Classifying

- Agitation Equipment

- Flotation

- Gravity Separation Equipment

- Magnetic Equipment

- Thickening

- Dewatering Machine

- Gold Extraction Equipment

- Feeding

- Transmission Equipment

- Iron Removal Equipment

- Automatic Control Equipment

- Wear – Resistant Rubber Products

- Valves

- Hydrocyclone

- Pumps

-

- Solutions

-

- Gold CIP Production Line

- Gold CIL Processing Line

- Gold Flotation Production Line

- Cu-Pb-Zn Dressing Process

- Gold Heap Leaching Process

- Molybdenum Dressing Production Line

- Quartz Sand Dressing Production Line

- Hematite Separation Process

- Phosphorite Flotation Equipment Production Line

- Manganese Ore Magnetic Separation Production Line

- Magnetite Separation Production Line

- Scheelite Flotation Production Line

- Fluorite Flotation Process

- Silver Flotation Process

- Barite Mineral Processing

- Antimony Mineral Processing

- Wolframite Mineral Processing

- Chrome Ore Mining Process

- Iron Ore Mining Process

- Tin Ore Mining Process

- Nickel Ore Mining Process

- Graphite Ore Beneficiation Process

- Tailings Re-Processing Line

- Titanium Mining Process

- Dolomite Mining Process

- Kaolin Mining Process

- Pyrite Mineral Process

- Zircon Ore Mining Process

- Magnesite Flotation Process

- More >>>

-

- Cases

- News

- Contact Us

Pyrite Mineral Process

【Process Introduction】

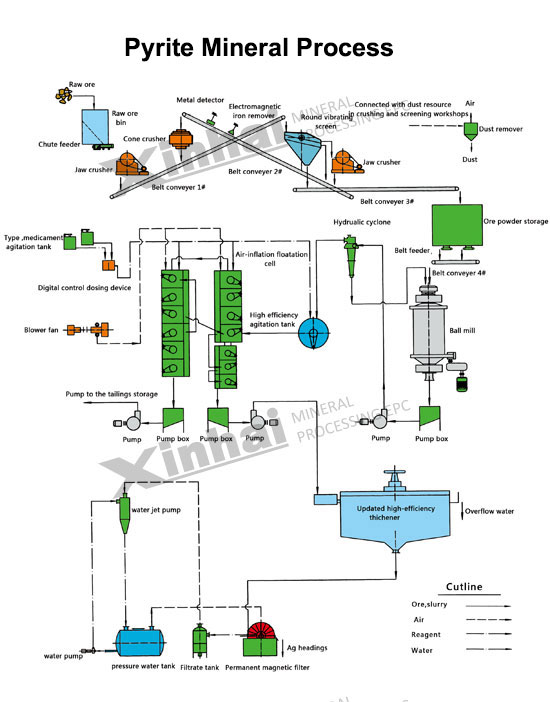

Pyrite ore is a kind of vital mineral mine which mainly used for manufacturing sulfuric acid. Pyrite occurs in numerous shapes and habits. Concentrating equipment are mainly used in the process of Pyrite ore, including jig, concentrating table, and spiral classifier, etc.

【Application】

There are two main separating solution for Pyrite, gravity separation and flotation separation. Gravity separation is most commonly used.

Check Process Flow >>

[Process Introduction]

Gravity Separation

Gravity separation characterized by high efficiency and energy saving, which is most highly used in mineral process, since it is strongly practicability and has more effects than separation in mining efficiency and mining index. For less investment and mineral cost as well as little pollution, gravity separation is more suitable for coarse particle size pyrite processing.

Jig is the mainly processing machine when adopting gravity separation. Which is the results of comprehensively consideration of pyrite disseminated extent and processing capacity. As pyrite ore mostly has coarse particle size, qualified concentrate can be reached after crushing, grinding and separating. With large capacity, high recovery rate, jig can meet the needs of pyrite gravity.

Flotation Separation

As flotation also can be used for pyrite ore separation, though flotation separation has deficiency with considerable large investment in equipment, higher mining cost, while better efficiency and index in mining with simple flotation reagents, so flotation methods can be used for low grade pyrite ore.

Crushing, separating, grinding, classifying, flotation and concentrating is the main steps for flotation when processing pyrite.

[Case ]

A case of Xinhai pyrite ore mining solutions, pyrite ore is extremely sliming. The previous plant applied the process of crushing, gravity separation and cleaning. This kind of process is defective, which cause the loss of fine tungsten ore, high investment, and even poor index. In order to promote the condition, Xinhai made a study of their ore features and process and optimized the Pyrite mineral processing, and finally adopted the flotation method to separate pyrite. By adding slime treatment in the process, the plant finally reach the ideal beneficiation indexes. Reconstruction completed,it could obviously strengthens the recovery of fine particle and reduces the impact of the mud on the separation process. The recovery index becomes better realizing the comprehensive recycling of resources.

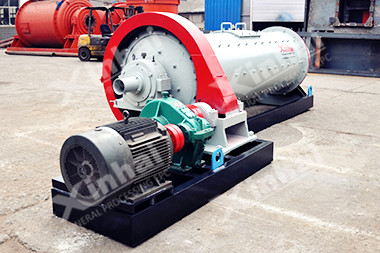

[Related Products]

[ Process Flow ]

Guestbook

Please leave your message here! We will send detail technical info and quotation to you!

Mineral Processing

EPC and Equipment

Tel: 0086 13025991453

E-mail: marketing@ytxinhai.com

Home

About us

EPC

Products

Solutions

Cases

News

Contact Us

3D Exhibition Room

sitemap

© 2014 Shandong Xinhai Mining Technology & Equipment Inc.