- Home

- About us

- Mineral Processing EPC

- Products

-

- Crushing

- Screening

- Grinding

- Classifying

- Agitation Equipment

- Flotation

- Gravity Separation Equipment

- Magnetic Equipment

- Thickening

- Dewatering Machine

- Gold Extraction Equipment

- Feeding

- Transmission Equipment

- Iron Removal Equipment

- Automatic Control Equipment

- Wear – Resistant Rubber Products

- Valves

- Hydrocyclone

- Pumps

-

- Solutions

-

- Gold CIP Production Line

- Gold CIL Processing Line

- Gold Flotation Production Line

- Cu-Pb-Zn Dressing Process

- Gold Heap Leaching Process

- Molybdenum Dressing Production Line

- Quartz Sand Dressing Production Line

- Hematite Separation Process

- Phosphorite Flotation Equipment Production Line

- Manganese Ore Magnetic Separation Production Line

- Magnetite Separation Production Line

- Scheelite Flotation Production Line

- Fluorite Flotation Process

- Silver Flotation Process

- Barite Mineral Processing

- Antimony Mineral Processing

- Wolframite Mineral Processing

- Chrome Ore Mining Process

- Iron Ore Mining Process

- Tin Ore Mining Process

- Nickel Ore Mining Process

- Graphite Ore Beneficiation Process

- Tailings Re-Processing Line

- Titanium Mining Process

- Dolomite Mining Process

- Kaolin Mining Process

- Pyrite Mineral Process

- Zircon Ore Mining Process

- Magnesite Flotation Process

- More >>>

-

- Cases

- News

- Contact Us

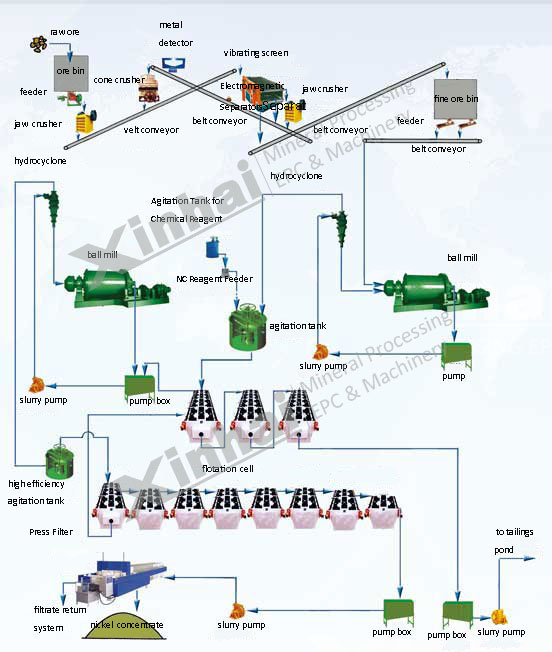

Nickel Ore Mining Process

【Process Introduction】

Nickel Ore can be divided into copper sulfide nickel ore and nickel oxide ore, flotation is the main beneficiation method when processing copper sulfide nickel ore, magnetic separating and gravity separating are the commonly auxiliary methods.

【Application】

Nickel ore beneficiation can be applied to process copper nickel ore accompanied by Pyrite and other gangue or nickel oxide ore.

Check Process Flow >>

[ Process Introduction ]

Mixing Flotation Process

The mixing flotation process is to separate nickel ore in which copper has lower content than Nickel, the mixed concentrate of copper and nickel will smelt into high grade nickel directly.

Mixing-preferably Flotation Process

Copper nickel can be get from raw ore, then the copper concentrate with low grade nickel and the nickel concentrate with low grade copper can be separate from the mixing concentrate, the nickel concentrate will be sent into the next stop-smelting, nickel matte can be get then separated.

Mixing-preferably Flotation then Nickel Recovery

When floatability differences happens to the various nickel element of the raw ore, then nickel ore can be recoveried further from tailings after the copper and nickel been mixing flotation.

Copper- Nickel Ore Flotation Process

When process copper-sulfide nickel ore, collector and frother will be used in order to better results. A basic principle of copper-sulfide nickel ore process is that it is better to let copper assimilate into nickel ore rather than the opposite. For it is easier to recovery cooper from nickel concentrate. The process has a vital advantage-receive copper concentrate with low grade nickel directly.

[ Cases ]

There is a large plant of copper-sulfide nickel ore in Ji Lin provice, China. Xinhai providing perfect beneficiation process of three-stage one close crushing, stage grinding, mixing-separating flotation, three stages dehydration of nickel concentrate and two stages dehydration of copper concentrate. This process characterized by easier operation, longer flotation time, fewer concentrate flotation and process concentrate ore from different stages of separation, which can recovery nickel ore as soon as possible in the flotation process. The solution of copper-sulfide nickel ore get nickel grade of 12% of high profit.

[Related Products]

[ Process Flow ]

Guestbook

Please leave your message here! We will send detail technical info and quotation to you!