- Home

- About us

- Mineral Processing EPC

- Products

-

- Crushing

- Screening

- Grinding

- Classifying

- Agitation Equipment

- Flotation

- Gravity Separation Equipment

- Magnetic Equipment

- Thickening

- Dewatering Machine

- Gold Extraction Equipment

- Feeding

- Transmission Equipment

- Iron Removal Equipment

- Automatic Control Equipment

- Wear – Resistant Rubber Products

- Valves

- Hydrocyclone

- Pumps

-

- Solutions

-

- Gold CIP Production Line

- Gold CIL Processing Line

- Gold Flotation Production Line

- Cu-Pb-Zn Dressing Process

- Gold Heap Leaching Process

- Molybdenum Dressing Production Line

- Quartz Sand Dressing Production Line

- Hematite Separation Process

- Phosphorite Flotation Equipment Production Line

- Manganese Ore Magnetic Separation Production Line

- Magnetite Separation Production Line

- Scheelite Flotation Production Line

- Fluorite Flotation Process

- Silver Flotation Process

- Barite Mineral Processing

- Antimony Mineral Processing

- Wolframite Mineral Processing

- Chrome Ore Mining Process

- Iron Ore Mining Process

- Tin Ore Mining Process

- Nickel Ore Mining Process

- Graphite Ore Beneficiation Process

- Tailings Re-Processing Line

- Titanium Mining Process

- Dolomite Mining Process

- Kaolin Mining Process

- Pyrite Mineral Process

- Zircon Ore Mining Process

- Magnesite Flotation Process

- More >>>

-

- Cases

- News

- Contact Us

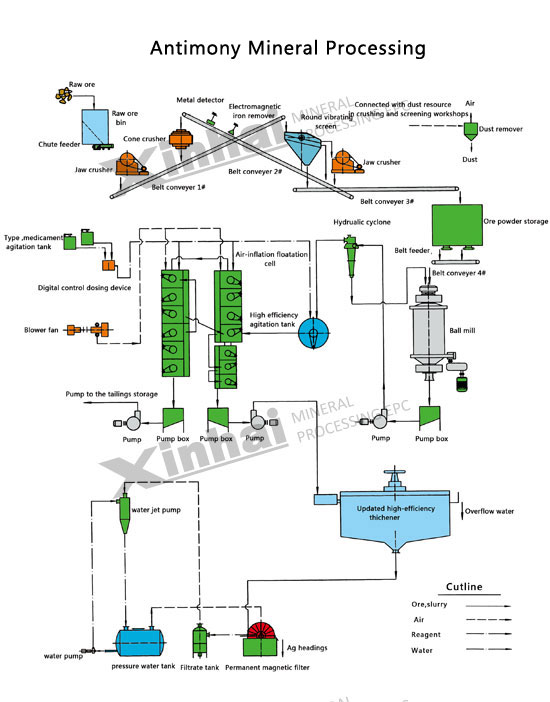

Antimony Mineral Processing

【Process Introduction】

Proportion of antimony ore is far greater than proportion of gangue, so it will be separated by using the method gravity separation. This method has many features, high efficiency, energy saving, and environment protection, which can make the low-grade ore enrichment advance. After gravity separation, the antimony will be purified by floatation. So the processing method of Xinhai is gravity separation-flotation process.

【Application】

Xinhai’s gravity separation-flotation process is applied to all kinds of antimony ore.

Check Process Flow >>

[Process Description]

Xinhai's gravity separation-flotation process

The ore after hand sorting will go through coarse crushing and fine crushing, during which the size of mineral should be under 30mm, and screening classification have three size fractions, 8-30mm, 2-8mm, 0-2mm. then the three kind of minerals will go respectively into Xinhai AM30 Jig, Xinhai LTA1010/2 Jig, and Xinhai Sawtooth Wave Jig to gravity separation. The mixted concentrate from the last stage will be go into the gravity concentrate district. Then after the process of gravity, there will be a process of flotation, the tailings from the preview gravity separation will be grinded, separated, stirred, and separated. And the flotation will apply the process of one roughing, three cleanings, and two scavenging. Then high grade antimony fine powder will be produced. The tailings from the flotation will be reelected by shaking table to recycle the fine antimony particles, which we can get high grade antimony concentrate and tailings.

[Case]

In one of Xinhai's project, antimony content is 3.19%, among which the share of antimony sulfide is about 95.30%, and a small amount of antimony is existed in valentinite or antimonite, about 4.70%. Carbon content of the ore is 6.43%, in which the inorganic carbon have up to 5.46%, and is antimony sulfide with high-carbon and very complex for dressing. After multi scheme of test, Xinhai finally decided to use gravity separation-flotation process to recycle the antimony ore, and in the test the grade of antimony is 58.71%, the recovery rate of mixed antimony concentrate Is 93.75%. xinhai achieved the maximum intensity of the recovery of the antimony ore, which reduced the environmental pollution caused by tailings and also gained excellent economic benefit.

[Related Products]

[ Process Flow ]

Guestbook

Please leave your message here! We will send detail technical info and quotation to you!

Mineral Processing

EPC and Equipment

Tel: 0086 13025991453

E-mail: marketing@ytxinhai.com

Home

About us

EPC

Products

Solutions

Cases

News

Contact Us

3D Exhibition Room

sitemap

© 2014 Shandong Xinhai Mining Technology & Equipment Inc.