- Home

- About us

- Mineral Processing EPC

- Products

-

- Crushing

- Screening

- Grinding

- Classifying

- Agitation Equipment

- Flotation

- Gravity Separation Equipment

- Magnetic Equipment

- Thickening

- Dewatering Machine

- Gold Extraction Equipment

- Feeding

- Transmission Equipment

- Iron Removal Equipment

- Automatic Control Equipment

- Wear – Resistant Rubber Products

- Valves

- Hydrocyclone

- Pumps

-

- Solutions

-

- Gold CIP Production Line

- Gold CIL Processing Line

- Gold Flotation Production Line

- Cu-Pb-Zn Dressing Process

- Gold Heap Leaching Process

- Molybdenum Dressing Production Line

- Quartz Sand Dressing Production Line

- Hematite Separation Process

- Phosphorite Flotation Equipment Production Line

- Manganese Ore Magnetic Separation Production Line

- Magnetite Separation Production Line

- Scheelite Flotation Production Line

- Fluorite Flotation Process

- Silver Flotation Process

- Barite Mineral Processing

- Antimony Mineral Processing

- Wolframite Mineral Processing

- Chrome Ore Mining Process

- Iron Ore Mining Process

- Tin Ore Mining Process

- Nickel Ore Mining Process

- Graphite Ore Beneficiation Process

- Tailings Re-Processing Line

- Titanium Mining Process

- Dolomite Mining Process

- Kaolin Mining Process

- Pyrite Mineral Process

- Zircon Ore Mining Process

- Magnesite Flotation Process

- More >>>

-

- Cases

- News

- Contact Us

Gold CIP Production Line

Gold CIP Production Line adsorbs gold from cyaniding pulp by active carbon including 7 steps: leaching pulp preparation, cyaniding leaching, carbon acid adsorption, gold loaded carbon desorption...

Gold CIL Processing Line

Gold CIL (Carbon in Leach) Process is an efficient design of extracting and recovering gold from its ore. By cyaniding and carbon leaching crushed gold ore slurry simultaneously, CIL process lower the gold...

Gold Flotation Production Line

Flotation is widely used in gold processing. Flotation process maximizes the enrichment of gold into sulfide minerals. The tailings can be directly discharged.Xinhai Gold Flotation Production Line has become...

Cu-Pb-Zn Dressing Process

Cu-Pb-Zn Dressing Process is used for the Cu-Pb-Zn ore with complicated properties such as close symbiosis, difficult dissociation and oxidation, etc.Tibet Lead zinc Beatification Plant is one of our successful cases.

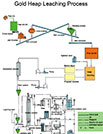

Gold Heap Leaching Process

Heap leaching (HL) is a flexible and economic mineral processing method, commonly used to extract gold from low-grade gold ores. In this process, ore is firstly crushed to fine particles...

Molybdenum Dressing Production Line

Molybdenum dressing production line can be used for single or refractory molybdenum with complex properties, containing a variety of minerals and oxidized serious. Xinhai can give you a better choice.

Quartz Sand Dressing Production Line

Quartz sand purification is removal of a small amount of impurities and the high difficulty separation technique to obtain refined quartz sand or high purity quartz sand. The purification technologies of quartz sand at...

Hematite Separation Process

Hematite separation process is suitable for complex structure hematite such as hematite and impurities with uneven distribution of particle size, ore with large content of fine particle, ore with small amount of magnetite...

Magnetite Separation Production Line

Magnetic separation places the leading position in iron ore separation. For weak magnetic and lean iron, Xinhai adopts gravity separation, magnetic separation, flotation, and roasting magnetic separation; used for strong...

Manganese Ore Magnetic Separation Production Line

Xinhai applies the magnetic process to separate manganese ore, including two stages, rough separate the high-intensity magnetic ore and concentrate...

Phosphorite Flotation Equipment Production Line

According to different ore properties of phosphate, Xinhai designs many processes for it such as flotation, gravity separation, chemical leaching...

Scheelite Flotation Production Line

Scheelite dressing can use gravity, magnetic and flotation separation. The types and properties of the ore decide the separation methods and processes. Basing on good floatability of scheelite, the flotation is selected...

Fluorite Flotation Process

Process methods of fluorite ore are gravity separation and flotation. Mineral processing equipment includes gravity separation equipment and flotation equipment; gravity separation equipment: jig, only jig can deal with...

Silver Flotation Process

Silver flotation process of Xinhai includes three kinds of methods: flotation, flotation & gravity separation, flotation & cyaniding.Flotation & cyaniding method is the most important process among the whole...

Barite Mineral Processing

For the gravity separation of barite, the process of Xinhai is crushing, screening and jigging. Then the high grade (over 80%) concentrate will be produced. Jig is the main equipment for the separation and purification...

Antimony Mineral Processing

Proportion of antimony ore is far greater than proportion of gangue, so it will be separated by using the method gravity separation. This method has many features, high efficiency, energy saving, and environment...

Wolframite Mineral Processing

Wolframite consists of the quartz dyke type ores and veinlet tungsten ores. Dissemination size of ores is relatively coarse, so it is easy to separation. Xinhai wolframite mineral processing is a combined separating ...

Chrome Ore Mining Process

Chrome ore deposits are mined by both underground and surface techniques. most chrome ore must be processed by the chrome ore processing plants.so the mainly used chrome ore concentrating equipments are ore...

Iron Ore Mining Process

There are a lot of iron ore in nature, which containes highly quantities of hematite or magnetite.The mainly iron ore beneficiation method is magnetic separation and flotation separation,so the mainly used iron ore equipments ...

Tin Ore Mining Process

The density of tin ore is larger than the paragenetic mineral, so the mining process of tin ore apply gravity separation. However, all kinds of Iron oxides exist in those ore, like magnetite, hematite, etc., which cannot...

Nickel Ore Mining Process

Nickel Ore can be divided into copper sulfide nickel ore and nickel oxide ore, flotation is the main beneficiation method when processing copper sulfide nickel ore, magnetic separating and gravity separating are the...

Graphite Ore Beneficiation Process

Crystalline graphite and flake graphite has naturally floatability, thus Xinhai usually adopts flotation separation to process graphite from raw ore. Gravity separation mixing with flotation method can also be applied...

Tailings Re-Processing Line

Xinhai tailings re-processing line, with the thought of protecting ecosystem and fully using resources, provide a re-processing for tailings of iron, gold, Lead-zinc, copper, fluorite, and so on. Xinhai can design reasonable...

Titanium Mining Process

Titanium concentrate is the raw material of Titanium Dioxide. Xinhai titanium mining process including gravity & flotation process, magnetic & flotation process, classification joint beneficiation.

Dolomite Mining Process

Dolomite mining process is the solution of separating dolomite concentrate from Dolomite raw ore. Based on mosaic structure of the Dolomite mine and years of mining process experiences, Xinhai applying Dolomite mining process of two-stage crushing, washing, then three-stage separating, flotation process will be used to process Dolomite with complex structures.

Kaolin Mining Process

Dry & wet separation are the two main Kaolin mining process of Xinhai. Dry separation process is characterized by easy operation and saving cost.Xinhai wet separation process applying high gradient magnetic separation(HGMS), froth flotation and selective flocculant to make full use of Kaolin mine resources.

Pyrite Mineral Process

Pyrite ore is a kind of vital mineral mine which mainly used for manufacturing sulfuric acid. Pyrite occurs in numerous shapes and habits. Concentrating equipment are mainly used in the process of Pyrite ore, including jig, concentrating table, and spiral classifier, etc.

Zircon Ore Mining Process

Zircon ore mining process is the process of remove the impurity and promote the content of zircon. According to the characteristic of raw ore, Xinhai design methods of gravity separation, magnetic separation, flotation separation, or combined those methods

Magnesite Flotation Process

Magnesite is a carbonate mineral. Xinhai mainly applied direct flotation process and Reverse Flotation Process for beneficiation of magnesite.

Guestbook

Please leave your message here! We will send detail technical info and quotation to you!

Mineral Processing

EPC and Equipment

Tel: 0086 13025991453

E-mail: marketing@ytxinhai.com

Home

About us

EPC

Products

Solutions

Cases

News

Contact Us

3D Exhibition Room

sitemap

© 2014 Shandong Xinhai Mining Technology & Equipment Inc.