- Home

- About us

- Mineral Processing EPC

- Products

-

- Crushing

- Screening

- Grinding

- Classifying

- Agitation Equipment

- Flotation

- Gravity Separation Equipment

- Magnetic Equipment

- Thickening

- Dewatering Machine

- Gold Extraction Equipment

- Feeding

- Transmission Equipment

- Iron Removal Equipment

- Automatic Control Equipment

- Wear – Resistant Rubber Products

- Valves

- Hydrocyclone

- Pumps

-

- Solutions

-

- Gold CIP Production Line

- Gold CIL Processing Line

- Gold Flotation Production Line

- Cu-Pb-Zn Dressing Process

- Gold Heap Leaching Process

- Molybdenum Dressing Production Line

- Quartz Sand Dressing Production Line

- Hematite Separation Process

- Phosphorite Flotation Equipment Production Line

- Manganese Ore Magnetic Separation Production Line

- Magnetite Separation Production Line

- Scheelite Flotation Production Line

- Fluorite Flotation Process

- Silver Flotation Process

- Barite Mineral Processing

- Antimony Mineral Processing

- Wolframite Mineral Processing

- Chrome Ore Mining Process

- Iron Ore Mining Process

- Tin Ore Mining Process

- Nickel Ore Mining Process

- Graphite Ore Beneficiation Process

- Tailings Re-Processing Line

- Titanium Mining Process

- Dolomite Mining Process

- Kaolin Mining Process

- Pyrite Mineral Process

- Zircon Ore Mining Process

- Magnesite Flotation Process

- More >>>

-

- Cases

- News

- Contact Us

Magnetite Separation Production Line

【Process Introduction】

Magnetic separation places the leading position in iron ore separation. For weak magnetic and lean iron, Xinhai adopts gravity separation, magnetic separation, flotation, and roasting magnetic separation; used for strong magnetic iron ore, magnetic separation

【Application】

Magnetite Separation Production Line is used to single magnetite with simple ore properties

Check Process Flow >>

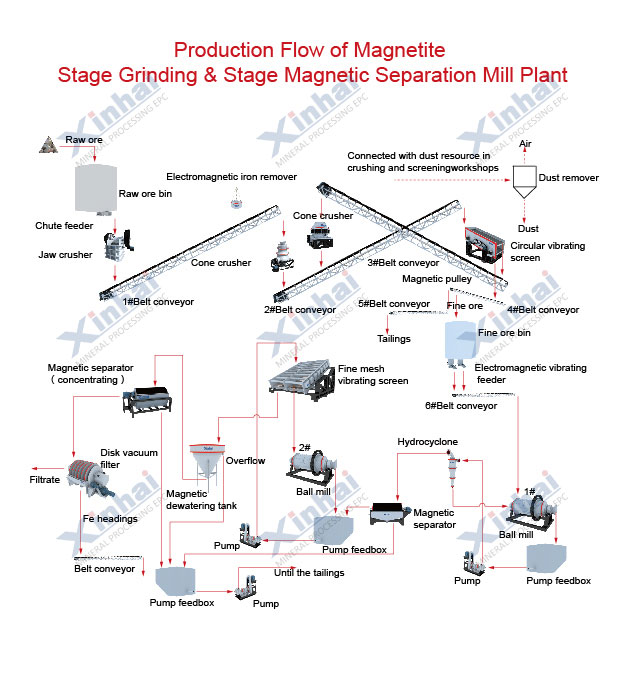

[Process Description]

Strong magnetic iron ore separation process

It is used to low grade magnetite. Due to the strong magnetic and easy to grind, one stage grinding is adopted for magnetite with coarse particle distribution, conversely the multi stages grinding. At present the fine grinding technology promoted by Xinhai improves the concentrate grate from 61% to 67%

Weak magnetic iron ore separation process

Weak magnetic mineral could use the strong magnetic mineral separation process after the magnetizing and roasting

Fine Grinding

In two stages grinding, stages separation, single weak magnetic flow, fine grinding means adding fine screen regrinding process to separate fine minerals timely and reduce the over-grinding. It improves the capacity of ball mill and concentrate grade by 2%

[Case ]

Case 1

Ilmenite Beneficiation Plant in Ecuador, a republic in northwestern South America, is one of our successful cases. This is 3D demo Video of the dressing plant created by our company.

Case 2

A magnetite in Inner Mongolia, the main mental mineral was magnetite with disseminated structure and fine particle distribution. The iron content was about 12-16%. This plant adopted the grinding-weak magnetic process and obtained 65% concentrate grade and 90% recovery rate, but the operation cost is too high after a long time running. It authorized Xinhai to reform the process. Xinhai did not only keep the original indexes, but also reduce the operation costs. Indexes comparison as follow

| Comparison of Reformation | Process | Iron Concentrate Grade /% | Iron Concentrate Recovery Rate /% |

| Before Reformation | Three stages grinding, Three stages magnetic separation | 65.58 | 90.15 |

| After Reformation | Stages grinding, stages separation | 67.81 | 92.69 |

Due to the low grade of the iron ore, the stages grinding and stages separation could reduce energy consumption. Cost saving is the key of developing the mine. The fine grinding process has guide significance for similar iron ore

[Related Products]

[ Process Flow ]

Related Articles

Guestbook

Please leave your message here! We will send detail technical info and quotation to you!

Mineral Processing

EPC and Equipment

Tel: 0086 13025991453

E-mail: marketing@ytxinhai.com

Home

About us

EPC

Products

Solutions

Cases

News

Contact Us

3D Exhibition Room

sitemap

© 2014 Shandong Xinhai Mining Technology & Equipment Inc.