- Home

- About us

- Mineral Processing EPC

- Products

-

- Crushing

- Screening

- Grinding

- Classifying

- Agitation Equipment

- Flotation

- Gravity Separation Equipment

- Magnetic Equipment

- Thickening

- Dewatering Machine

- Gold Extraction Equipment

- Feeding

- Transmission Equipment

- Iron Removal Equipment

- Automatic Control Equipment

- Wear – Resistant Rubber Products

- Valves

- Hydrocyclone

- Pumps

-

- Solutions

-

- Gold CIP Production Line

- Gold CIL Processing Line

- Gold Flotation Production Line

- Cu-Pb-Zn Dressing Process

- Gold Heap Leaching Process

- Molybdenum Dressing Production Line

- Quartz Sand Dressing Production Line

- Hematite Separation Process

- Phosphorite Flotation Equipment Production Line

- Manganese Ore Magnetic Separation Production Line

- Magnetite Separation Production Line

- Scheelite Flotation Production Line

- Fluorite Flotation Process

- Silver Flotation Process

- Barite Mineral Processing

- Antimony Mineral Processing

- Wolframite Mineral Processing

- Chrome Ore Mining Process

- Iron Ore Mining Process

- Tin Ore Mining Process

- Nickel Ore Mining Process

- Graphite Ore Beneficiation Process

- Tailings Re-Processing Line

- Titanium Mining Process

- Dolomite Mining Process

- Kaolin Mining Process

- Pyrite Mineral Process

- Zircon Ore Mining Process

- Magnesite Flotation Process

- More >>>

-

- Cases

- News

- Contact Us

Overflow Type Ball Mill

- Introduction

- A ball mill with simple structure

- Capacity

- 0.17~170t/h

- Product improvement

- Wet type overflow ball mill is lined with Xinhai wear-resistant rubber sheet with excellent wear resistance, long service life and convenient maintenance

Advantages

Jack-up device, easy maintenance

The hydrostatic and hydrodynamic bearings ensure the smooth operation

Low speed transmission is easy for starting and maintenance

The oil-mist lubrication device guarantees reliable performance of bearings

The gas clutch adopts the flexible start-up model

Products feature

The discharging of wet type overflow ball mill relies on the inclination because of the outlet hollow shaft diameter larger than inlet hollow shaft diameter. When the slurry surface is higher than outlet generatrix, the slurry overflow discharges from the mill

Product principle

The main component of wet overflow ball mill is a cylinder with bigger diameter and smaller length which is revolved by transmitting machinery. Materials are put in cylinder through the feed opening and then thoroughly grinded. The falling course of iron balls and ores can produce huge falling impact and autogenous grinding. The continuous feeding of ores can create considerable pressure to make ores move from feed opening toward discharge opening. Finally, acceptable particles are discharged from the discharge opening. Hollow shaft with the anti-spiral blade returns the steel ball and the coarse ore block.

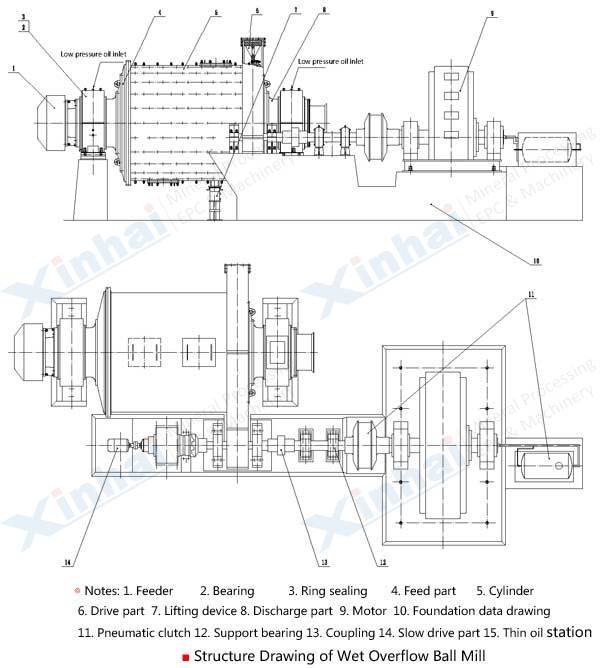

Product Structure

Wet type overflow ball mill works for fine fineness grinding.

Technical Parameters

| Model | Cylinder Diameter (mm) |

Cylinder Length (mm) |

Motor Model | Motor Power (kW) |

Length (mm) |

Width (mm) |

Height (mm) |

Effective Volume (m3) |

Max. Ball Load (t) | Weight (kg) |

| MQY0918 | 900 | 1800 | Y225M-8 | 22 | 5080 | 2300 | 2015 | 0.9 | 1.66 | 6078 |

| MQY1212 | 1200 | 1200 | Y225S-8 | 18.5 | 5788 | 2994 | 2540 | 1.14 | 2.4 | 11473 |

| MQY1224 | 1200 | 2400 | YR280S-8 | 55 | 6112 | 2794 | 2540 | 2.28 | 3.8 | 12308 |

| MQY1515 | 1500 | 1500 | JR115-8 | 60 | 5766 | 2945 | 2600 | 2.2 | 6.4 | 15424 |

| MQY1530 | 1500 | 3000 | JR125-8 | 95 | 7979 | 2945 | 2600 | 5 | 10 | 18690 |

| MQY2122 | 2100 | 2200 | JR128-8 | 155 | 8070 | 4840 | 3795 | 6.6 | 14 | 47800 |

| MQY2130 | 2100 | 3000 | JR137-8 | 210 | 8870 | 4840 | 3795 | 9 | 20 | 47220 |

| MQY2136 | 2100 | 3600 | JR137-8 | 210 | 9300 | 4840 | 3795 | 10.8 | 22 | 52010 |

| MQY2145 | 2100 | 4500 | JR148-6 | 310 | 11029 | 4738.6 | 3300 | 13.5 | 23.8 | 58305 |

| MQY2430 | 2400 | 3000 | JR1410-8 | 280 | 9710 | 4778 | 4120 | 12.1 | 23 | 65880 |

| MQY2721 | 2700 | 2100 | JR1410-8 | 280 | 9400 | 5600 | 4700 | 10.7 | 24 | 63900 |

| MQY2736 | 2700 | 3600 | TDMK400-32 | 400 | 13049 | 5800 | 4680 | 17.8 | 32 | 96570 |

| MQY2740 | 2700 | 4000 | TDMK400-32 | 400 | 11850 | 5667 | 4496 | 20.4 | 40 | 78800 |

| MQY3231 | 3200 | 3100 | TDMK630-36 | 630 | 12750 | 6760 | 5150 | 21.4 | 45 | 107660 |

| MQY3245 | 3200 | 4500 | TDMK630-36 | 630 | 14356 | 7200 | 5152.5 | 32.8 | 65 | 130283 |

| MQY3254 | 3200 | 5400 | TM1000-36/2600 | 1000 | 15800 | 6760 | 5200 | 37.2 | 73 | 121000 |

| MQY3645 | 3600 | 4500 | TM1000-36/2600 | 1000 | 15000 | 7200 | 6326 | 41.8 | 76 | 135000 |

| MQY3650 | 3600 | 5000 | TM1250-40/3250 | 1250 | 17157 | 7755 | 6326 | 46.4 | 86 | 145000 |

| MQY3660 | 3600 | 6000 | TM1250-40/3250 | 1250 | 19000 | 7755 | 6326 | 55.7 | 102 | 154000 |

| MQY3690 | 3600 | 9000 | TDMK1800-30 | 1800 | 28000 | 4600 | 5600 | 83 | 163 | 212000 |

| MQY3867 | 3800 | 6700 | TDMK1600-30 | 1600 | 19000 | 8200 | 7100 | 70 | 130 | 186000 |

| MQY4067 | 4000 | 6700 | TDMK1800-30 | 1800 | 15600 | 9600 | 7300 | 78 | 138 | 207000 |

| MQY4561 | 4500 | 6100 | TDMK2200-30 | 2200 | 18200 | 10500 | 7600 | 93 | 151 | 238000 |

Related Articles

Guestbook

Please leave your message here! We will send detail technical info and quotation to you!

Related Products

Raymond Mill | Cylinder Energy-Saving Overflow Ball Mill | Autogenous Mill |

Mineral Processing

EPC and Equipment

Tel: 0086 13025991453

E-mail: marketing@ytxinhai.com

Home

About us

EPC

Products

Solutions

Cases

News

Contact Us

3D Exhibition Room

sitemap

© 2014 Shandong Xinhai Mining Technology & Equipment Inc.