- Home

- About us

- Mineral Processing EPC

- Products

-

- Crushing

- Screening

- Grinding

- Classifying

- Agitation Equipment

- Flotation

- Gravity Separation Equipment

- Magnetic Equipment

- Thickening

- Dewatering Machine

- Gold Extraction Equipment

- Feeding

- Transmission Equipment

- Iron Removal Equipment

- Automatic Control Equipment

- Wear – Resistant Rubber Products

- Valves

- Hydrocyclone

- Pumps

-

- Solutions

-

- Gold CIP Production Line

- Gold CIL Processing Line

- Gold Flotation Production Line

- Cu-Pb-Zn Dressing Process

- Gold Heap Leaching Process

- Molybdenum Dressing Production Line

- Quartz Sand Dressing Production Line

- Hematite Separation Process

- Phosphorite Flotation Equipment Production Line

- Manganese Ore Magnetic Separation Production Line

- Magnetite Separation Production Line

- Scheelite Flotation Production Line

- Fluorite Flotation Process

- Silver Flotation Process

- Barite Mineral Processing

- Antimony Mineral Processing

- Wolframite Mineral Processing

- Chrome Ore Mining Process

- Iron Ore Mining Process

- Tin Ore Mining Process

- Nickel Ore Mining Process

- Graphite Ore Beneficiation Process

- Tailings Re-Processing Line

- Titanium Mining Process

- Dolomite Mining Process

- Kaolin Mining Process

- Pyrite Mineral Process

- Zircon Ore Mining Process

- Magnesite Flotation Process

- More >>>

-

- Cases

- News

- Contact Us

Home > Beneficiation > Gold >Refractory Gold Ore Processing

Refractory Gold Ore Processing

Process Introduction

Refractory Gold Ore Processing is an efficient method to process refractory gold ore. By directly using conventional cyanidation methods, the recovery rate of gold is low. So pre-treatment of refractory gold ore is added to the processing line, which increased improve enterprise production benefit.

Application: Refractory Gold Ore Processing is always adopted to process the gold ore that generally contains organic carbon, sulfide minerals, arsenic, antimony, and so on. After pre-treatment of the refractory gold ore, flotation method or standard cyanidation and carbon adsorption processes is used to process it, and finally get gold concentrate.

Introduction

Process Flow

Cases

Introduction of Process & Products

Pre-treatment of refractory gold ore

Pre-treatment of refractory gold ore is aimed at free the gold from occluding of sulfide minerals and so on, which making it difficult for the leaching or flotation solution. Now there are several method to do pre-treat, Roasting, Bio-oxidation or Bacterial oxidation, Pressure oxidation, Chemical Oxidation and so on. By using those method, so that the other mineral composition in refractory gold ore can be effective separated out, which can increased the gold recovery rate in the following process.

Gold Flotation & CIP processing

Gold Flotation Process is use to process fine gold, sulfide gold-containing quartz ore, multi metal gold-containing sulfide ore and carbon-containing ore. Xinhai flotation cell has world class quality, lower price, which is worth your trust.

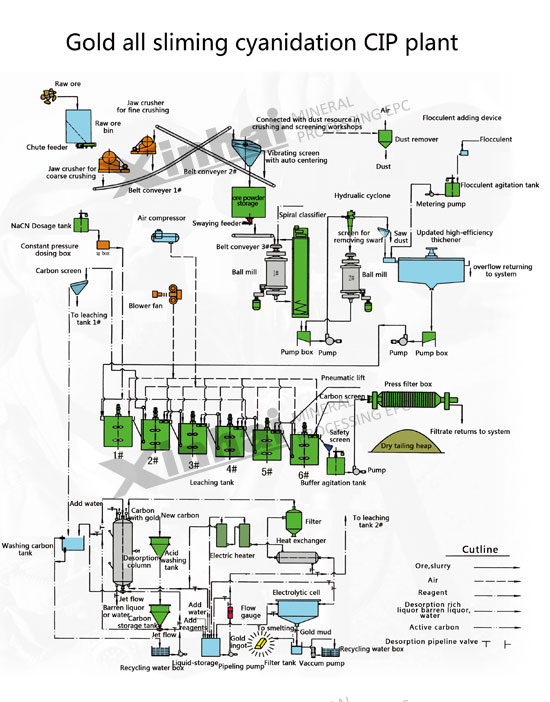

There are two kinds of ore suitable for gold CIP production line: flotation gold concentrate, amalgamation and gravity tailings; mudded oxidized ore. This method adsorbs gold from cyaniding pulp by active carbon including 7 steps: leaching pulp preparation, cyaniding leaching, carbon adsorption, gold loaded carbon desorption, pregnant solution electrodeposit, carbon regeneration, leaching pulp. By using Leaching Agitation Tank and Desorption Electrolysis System produced by Xinhai can efficiently recover the gold from ore and get high recovery rate.

Process Flow

Tanzania 1200tpd Gold Mineral Process Plant

Tanzania 1200tpd gold mineral processing project has finished the installation and commissioning part recently, now has been put into operation, during the installation and commissioning process, Xinhai employees carry forward the work style of working hard and develop the rigorous attitude to guarantee high quality finishment of the work in short period. The production line has got anticipated recovery rate, Xinhai employees got highly appreciated from the customer.

Thickener Construction

Factory Construction

Construction Worker

[Related Process]

Guestbook

Please leave your message here! We will send detail technical info and quotation to you!

Mineral Processing

EPC and Equipment

Tel: 0086 13025991453

E-mail: marketing@ytxinhai.com

Home

About us

EPC

Products

Solutions

Cases

News

Contact Us

3D Exhibition Room

sitemap

© 2014 Shandong Xinhai Mining Technology & Equipment Inc.