Ⅰ Mineral Dressing Test

The test was mainly for the recycle of graphite. The sample for test was prepared and sent by client. The raw ore would be ground first, and then after one roughing- two scavenging-ten cleaning, the test would finally receive output 14.2% , fixed carbon content 92.30%, the recovery rate 87.91%. In order to get some of high-carbon graphite, the graphite concentrate would be into wet screening, then the +140mm concentrate output 3.68%, fixed carbon content 95%; -140mm concentrate output 10.72%, fixed carbon content 91.46%. (Attached PDF of Test Report).

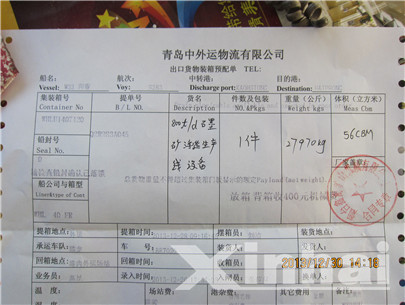

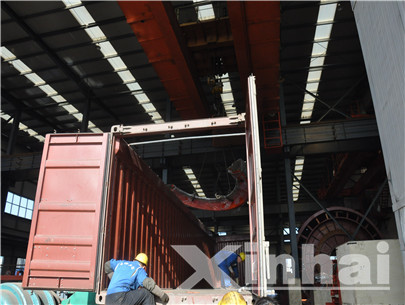

Ⅱ Packaging and Shipping

Mining equipment manufactured by Xinhai were about to pack and ship.

PACK & SHIP

Ⅲ Equipment Schedule

According to the client requirement, the followings were the mining equipment for this project.

| Name of equipment | Model | amount | Motor Power(KW) | voltage(V) |

| Vibrating Feeder | ZSW-380*95 | 1 | 11 | 380 |

| Jaw crusher | PE500×750 | 1 | 55 | 380 |

| Impact crusher | PFCQ1010 | 1 | 90 | 380 |

| Round Vibrating Screen | YA1548 | 1 | 15 | 380 |

| Belt Conveyor | TD75-8063 | 3 | 15 | 380 |

| Belt Feeder | PG650×1500 | 2 | 2*2.2 | 380 |

| High Spiral Classifier | FLGT-2000 | 1 | 18 | 380 |

| Grid Type Ball Mill | MQT1557 | 1 | 132 | 380 |

| High Efficiency Agitation Tank | GBJ-2500×2500 | 1 | 15 | 380 |

| High Efficiency Agitation Tank | GBJ-2000×2000 | 1 | 7.5 | 380 |

| Flotation | SF-8 | 3 | 3*30 | 380 |

| Flotation | JJF-8 | 7 | 7*22 | 380 |

| Flotation | SF-4 | 3 | 3*15 | 380 |

| Flotation | JJF-4 | 9 | 9*11 | 380 |

| Flotation | SF-2.8 | 33 | 33*11 | 380 |

| Auger conveyor | LXG-Φ250×4000 | 1 | 5.5 | 380 |

| Agitation Tank for Chemical Reagent | BJW-2000×2000 | 1 | 5.5 | 380 |

| Press Filter | XMZ-200/1250 | 2 | 2*4 | 380 |

| Submerged Slurry Pump | 65QV-SP | 5 | 5*7.5 | 380 |

Ⅳ Installation of Equipment

Related equipment were set up, so the engineers teem was doing installation and commission.

INSTALLATION

Ⅵ Commission of Equipment

Related equipment were set up, so the engineers teem was doing installation and commission.

COMMISSION

Ⅶ Personnel Training

In order to help workers to be familiar with their works as soon as possible, Xinhai technicist did practical operation training for them, and helped workers pay attention to some details which was usually uneasy to be noticed but extremely important.It could build their own technical team and lay the foundation for the stable operation later.

TRAINING

Ⅷ Designed Capacity Reached

Vietnam Kra 800tpd graphite ore dressing plant project finally got the recovery rate 92%. Prospective earnings was 48 million dollars. Xinhai provided one-stop service for this project, including mineral testing, engineer design, equipment manufacture, installation & commissioning and local training and designed capacity reached. Xinhai is focused on providing the most professional mineral equipment and solution for clients.

Graphite Ore

800t/dSOLUTIONS

Capacity Reached

Mineral Processing

EPC and Equipment

Tel: 0086 15311826765

E-mail: marketing@ytxinhai.com

Home

About us

EPC

Products

Solutions

Cases

News

Contact Us

3D Exhibition Room

sitemap

© 2014 Shandong Xinhai Mining Technology & Equipment Inc.